How Apache used existing edge infrastructure to increase efficiency and lower well costs

Optimizing and leveraging existing edge infrastructure through seamless real-time data integration with Tatsoft.

Add bookmark

We respect your privacy, by clicking "Download Your Copy" you agree to having your details passed onto the sponsor who may promote similar products and services related to your area of interest subject to their privacy policy. You have the right to object. In addition, you will receive our e-newsletter, including information on related online learning opportunities. For further information on how we process and monitor your personal data, and information about your privacy and opt-out rights, click here.

In today’s Digital Transformation frenzy falling behind the greatest and latest is quite common. That is not always considered a bad practice, especially when 'state of the art systems' haven’t been fully tested across different scenarios. This is particularly challenging in the Oil & Gas industry where safety is the number one priority and replacing or revamping the existing working environment is not a simple task. As a matter of fact, it is in most cases a complex process involving several disciplines, sophisticated equipment, and human resources all working together within a tight yet comprehensive schedule.

Apache Corporation wanted an innovative yet affordable solution to improve their well performance, by leveraging a variety of different information sources and real-time data at its Permian Basin operations. That's where Tatsoft came in.

Tatsoft’s FrameworX agnostic and non-intrusive platform enables operators to give their existing infrastructure a “face lift” by building additional intelligence layers and new functionality using a fully integrated development tool; which is also scalable from the edge to cloud and from right-sized to unlimited.

Download this exclusive case study featuring Apache Corporation and learn how Tatsoft can assist you in:

- Remote asset monitoring and advanced visualization interfaced to existing SCADA / Historian systems

- Drilling optimization using real-time streaming data and Artificial Intelligence

- Industry 4.0 driven, innovative and affordable IIoT platform to integrate, process, and visualize critical operational information

This article will also cover:

Augmented Industrial IoT connectivity and interoperability.

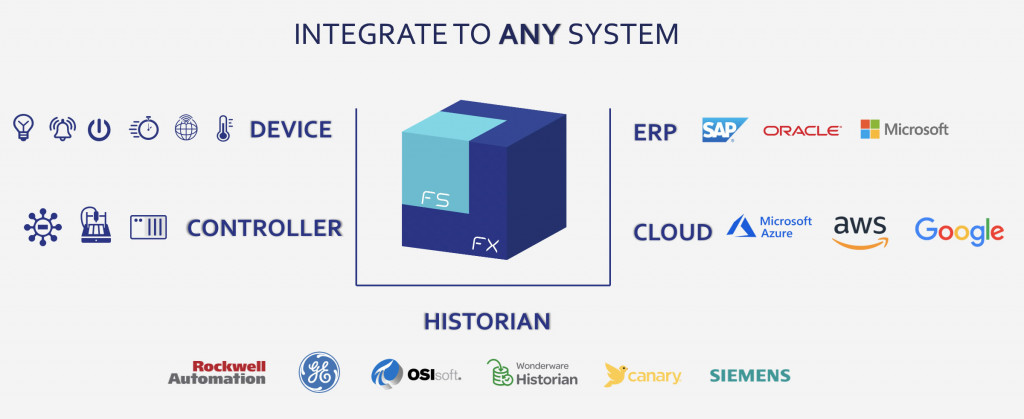

FrameworX/Tatsoft’s technology is built based on industry standards such as OPC UA, MQTT, WITSML. This guarantees the highest level of interoperability while securing a reliable data flow, exchange, and connectivity to any SCADA, PLC, RTU, or Historian.

Better decision-making, improved productivity, and efficiency.

Tatsoft provides an innovative, open, and affordable SCADA and Industrial IoT software platform that allows enterprises to monitor, integrate, process, and visualize critical operational information. Real-time data combined with remote access and control of your facilities and assets from anywhere allows for more informed operational adjustments and faster Decision-Making.

Integrate and Augment Any System:

Download your copy today and learn more about Tatsoft's offering.

We respect your privacy, by clicking "Download Your Copy" you agree to having your details passed onto the sponsor who may promote similar products and services related to your area of interest subject to their privacy policy. You have the right to object. In addition, you will receive our e-newsletter, including information on related online learning opportunities. For further information on how we process and monitor your personal data, and information about your privacy and opt-out rights, click here.